Navigation

Home

Home Contact Us

Contact Us Search the Site

Search the SiteThe ebbits Project

Project Overview

Project Overview The Platform

The Platform Try our ebbits on-line demos

Try our ebbits on-line demos Partners

Partners List of deliverables

List of deliverablesNewsroom

All News

All News Events

Events Conference publications

Conference publications Journal publications

Journal publications All project publications

All project publications ebbits in the press

ebbits in the press Video archive

Video archiveAffiliations

The ebbits project is affiliated with the following programs and organisations:

The ebbits project is active in the FInES cluster, the Future Internet Enterprise Systems (FInES) Cluster, where ebbits is leading the taskforces on international relations and manufacture and industry. Read more here.

The ebbits project is part of the Cluster of European projects on the Internet of Things. The Cluster aims to promote a common vision of the Internet of Things. ebbits is leading the taskforce on semantic interoperability

About us

The ebbits project is a 4-year project started in 2010. It is partly funded by the European Commission under the 7th Framework Programme in the area of Internet of Things and Enterprise environments under Grant Agreement no. 257852

Impressum

Impressum  Privacy

Privacy

Newsletter Subscription

Registered Members Only

Previous newsletters

Read previous issues of our newsletter here: September 2011

September 2011 August 2012

August 2012 August 2013

August 2013

June 2014

June 2014

March 2015

March 2015Popular Downloads

D5.1.1 Concept and Tec... D5.1.1 Concept and Tec... |

15000 |

Anonymous Networking ... Anonymous Networking ... |

9994 |

D3.8 Legal, IPR and li... D3.8 Legal, IPR and li... |

8968 |

The EBBITS Project: An... The EBBITS Project: An... |

7488 |

The Semantic Middlewar... The Semantic Middlewar... |

5419 |

Sign In

ebbits interactive OEEE calculator

This demo displays the front-end for the OEEE online calculator.

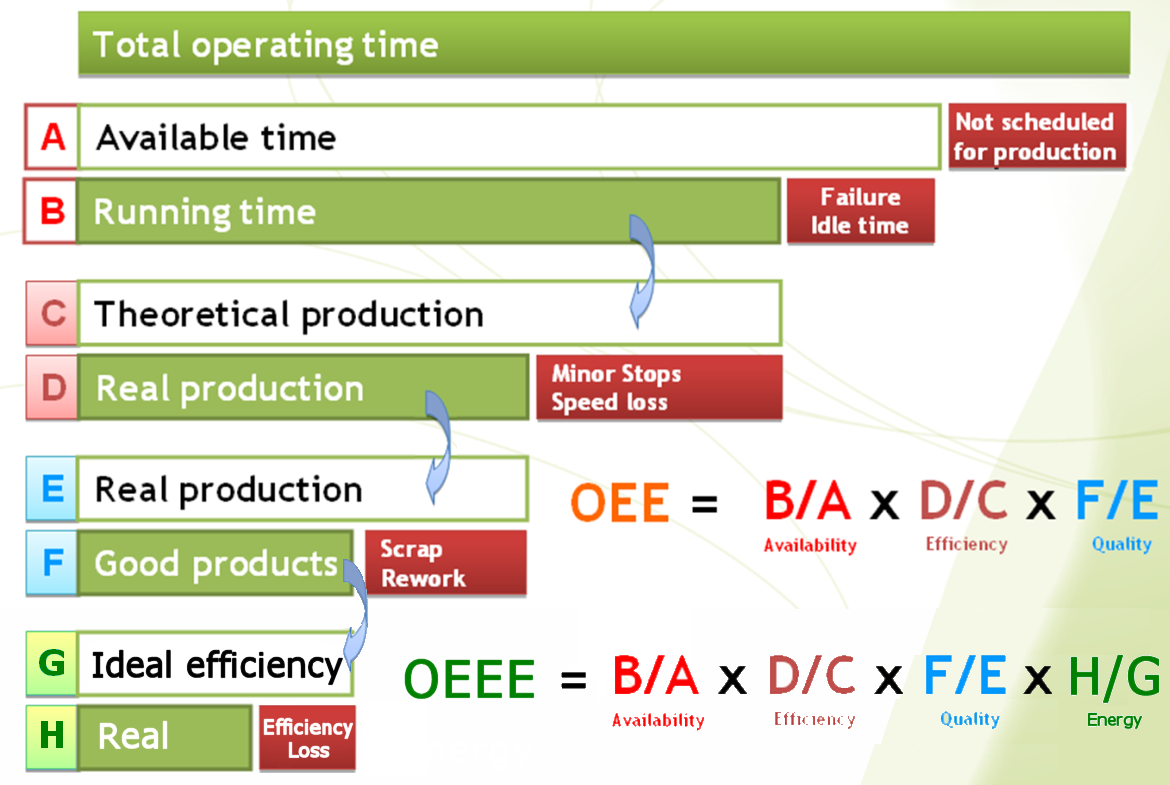

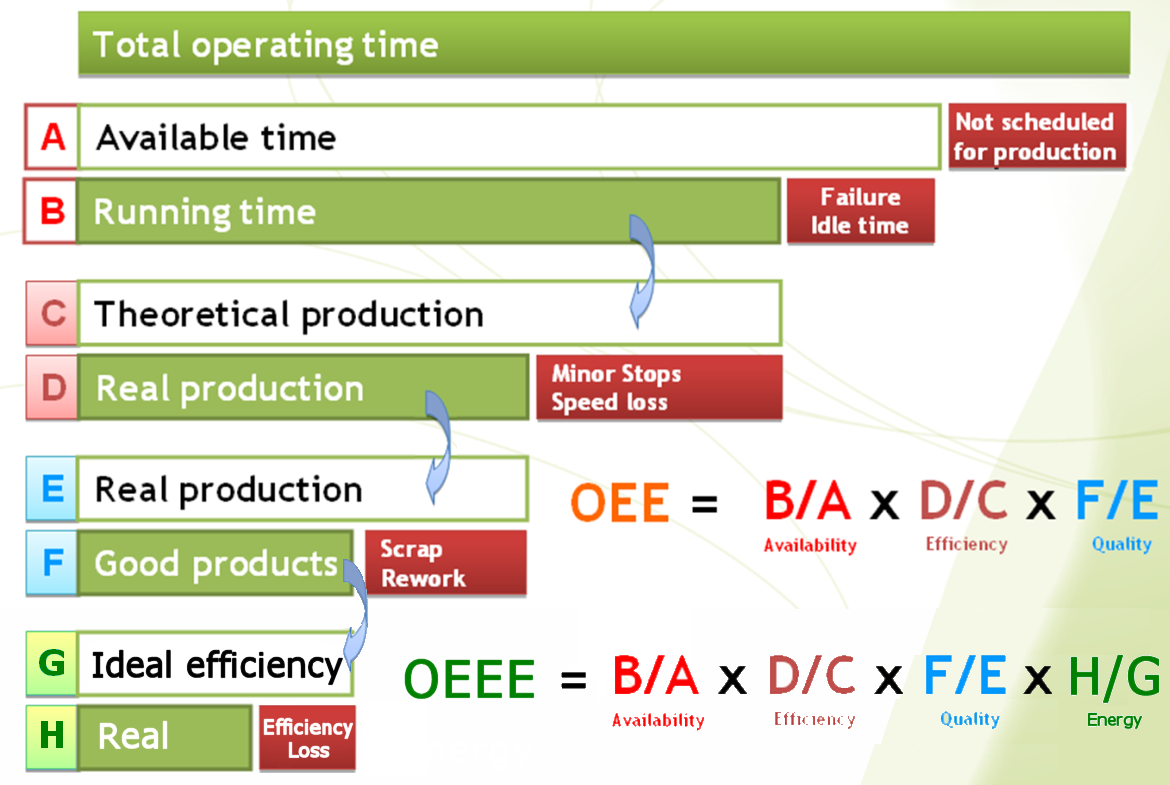

Presently, pure economic efficiency metrics guides the optimisation of vehicle manufacturing. However, manufacturing is a major consumer of energy. In order to support sustainability and facilitate interactions between actors in the supply chain, we have defined a new, total optimisation metrics by adding energy to the OEE index, thus creating a new key index, the OEEE Overall Equipment and Energy Efficiency index, with the following four components.

The OEEE index breaks the total performance of equipment into four separate and measurable components: Availability, Performance, Quality and Energy Efficiency:

Use the slides below to calculate the OEEE. First slide is for the availability index, next slide for the efficiency index, third slide for the quality indes and the bottom slide for the energy index. At the bottom the OEEE index is calculated.

Use the slides below to calculate the OEEE. First slide is for the availability index, next slide for the efficiency index, third slide for the quality indes and the bottom slide for the energy index. At the bottom the OEEE index is calculated.

In the real ebbits demonstrator, the data are automatically collected from the production line and the OEEE is dynamically calculated.

Presently, pure economic efficiency metrics guides the optimisation of vehicle manufacturing. However, manufacturing is a major consumer of energy. In order to support sustainability and facilitate interactions between actors in the supply chain, we have defined a new, total optimisation metrics by adding energy to the OEE index, thus creating a new key index, the OEEE Overall Equipment and Energy Efficiency index, with the following four components.

The OEEE index breaks the total performance of equipment into four separate and measurable components: Availability, Performance, Quality and Energy Efficiency:

- Availability looks at the downtime loss, which is the time the production is stopped, compared to the planned production time. Availability is a function of equipment failures, material shortages, and changeover time.

- The Performance component is also a function of downtime, changeover time and speed loss, i.e., factors that result in the process operating at less than maximum speed due to machine wear, misfeeds, and operator inefficiency.

- The Quality component depends on the amount of produced items that fails to meet quality standards and thus will have to be either rejected or reworked.

- The Energy component is a function of the actual energy efficiency of the real production process, i.e., how much energy is wasted compared to the most efficient process.

Use the slides below to calculate the OEEE. First slide is for the availability index, next slide for the efficiency index, third slide for the quality indes and the bottom slide for the energy index. At the bottom the OEEE index is calculated.

Use the slides below to calculate the OEEE. First slide is for the availability index, next slide for the efficiency index, third slide for the quality indes and the bottom slide for the energy index. At the bottom the OEEE index is calculated.In the real ebbits demonstrator, the data are automatically collected from the production line and the OEEE is dynamically calculated.

Comments

No Comments have been Posted.

Post Comment

Please Login to Post a Comment.